Whitefield, in east Bengaluru, has grown in two aspects. First, it is today known as the 'Silicon Valley of India', an area chock-a-block with some of the most popular software firms in the world. Second, its Inland Container Depot (ICD) has today grown to become the largest dry port in the country. The Dollar Business investigates the latter chapter of success.

Interview By Sisir Pradhan | June 2016 Issue | The Dollar Business

Traffic moving at a snail's pace isn’t an unusual sight in Bengaluru, the garden city of India. And the traffic at the road that leads to Inland Container Depot (ICD) Whitefield, the largest dry port in the country, isn’t any better.

In the 1980s, when visionaries zeroed down on Whitefield – a suburb in east Bengaluru – to build the ICD, the area was densely forested, and as such, isolated from the rest of the city. But over the years, the locality has grown to become the 'Silicon Valley of India', an area crowded with some of the largest multinational software companies in the world. So today, one does find it a job to reach the ICD, India’s first dry port.

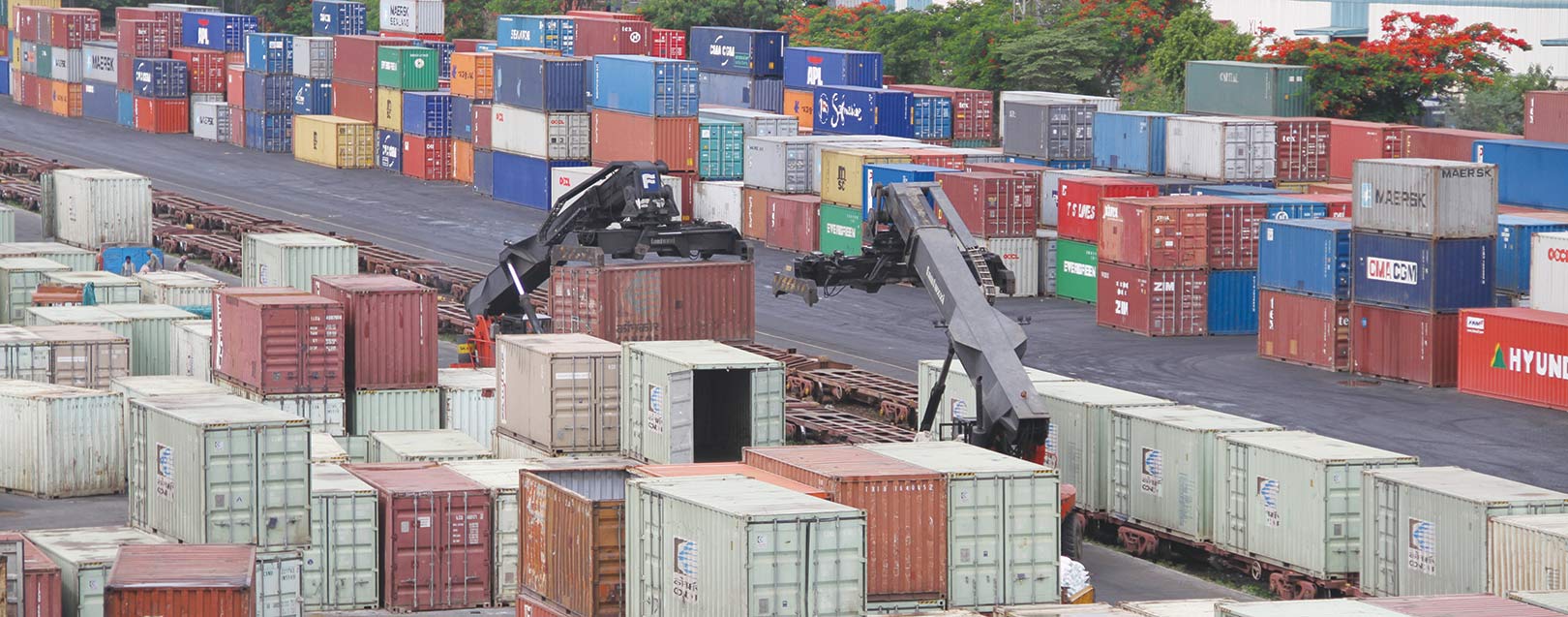

But once inside, it’s a world of its own, far removed from the bustling city. It’s a humongous enclosure, where massive and colourful containers are moved around-the-clock. In fact, in FY2015, ICD Whitefield registered a y-o-y growth of 15.53% in handling international container cargo and a 20.28% y-o-y jump in domestic container operations.

“Cheap labour, healthy business environment, and good weather condition make the city an ideal investment destination. Bengaluru is also a city which is well connected with other major cities in India as well as across the world, and houses some of the best known educational institutions. These are some of the reasons why people from different parts of the country relocate to the city. All these factors have influenced business houses to start operations in and around the city," Dr. Anup Dayanand Sadhu, Group GM, ICD Whitefield, Container Corporation of India (CONCOR), tells The Dollar Business, explaining the reasons behind the phenomenal success of this ICD.

The need for an inland container depot, in Bengaluru, was felt about three decades ago when it became almost difficult for importers to clear their goods that arrived by sea; importers were required to go to the sea port for receipt of goods and clearing. But today, ICD Whitefield provides a long list of facilities, including Customs service and other statutory authority clearances for imported goods received in containers at various sea ports. These containers are brought to ICD Whitefield by either rail or roadways and are custom bonded by the custodians i.e. Container Corporation of India Limited (CONCOR). Interestingly, this ICD initiated operations in 1981 at Bangalore Cantonment Railway Station, and was

later relocated to Whitefield.

The ICD at Whitefield is favourably connected to National Highways 4 and 7. It also provides train services to various ports across south India, apart from offering regular road trailer services to several parts of the country. There are 2-3 trains departing to Chennai Port on a daily basis loaded with export- (A high capacity reach stacker in operation at ICD Whitefield. The facility has seven such reach stackers. ) import cargo, two trains per week to Krishnapatnam Port, one train every 10 days to Cochin Port, and one train to ICD Tughlakabad every 7 to 10 days carrying domestic cargo. Although the ICD is located only 352 km from a major seaport at New Mangalore, traders prefer Chennai Port as the roads that lead to New Mangalore are not in good shape and cause delays to export-import consignments.

ICD Whitefield has a 128-acre land bank, leased out by South-Western Railways to CONCOR. The ICD has 12 warehouses scattered across a 40,000 sq. mt. area, and currently, nearly 90% of the warehousing capacity is occupied. The ICD has recently built another warehouse, spread over 1,500 sq. mt to accommodate its growing requirements. The facility at Whitefield also houses a customs bonded warehouse spread over 22,000 sq. mt of land and is capable of handling 50,000 TEUs (twenty feet equivalent units) per annum. It has two two-lane inspection complexes for the Customs to examine goods and ensure smooth clearances.

Reena Shetty, Additional Commissioner of Customs, Inland Container Depot, Whitefield, says that "apart from being a one-stop solution for Customs and other statutory clearances, terminal operators provide last mile connectivity to users." Terminal operators offer conveniences that can help ICD users save time and money – one such facility is picking goods from an exporter’s factory or doorstep delivery to an importer's godown.

Custom bonded goods stocked at ICD Whitefield. This ICD owns and runs the largest warehousing space in Bengaluru.

Since ICD Whitefield is a part of a large network owned by CONCOR, its users can avail end-to-end logistics solutions, which includes shipment of goods from the ICD Whitefield to any other CONCOR-operated container yard. “We have an integrated transport network comprising both road and rail, and now we are integrating coastal shipping into our logistic service. Moreover, since CONCOR has a pan-India presence, we can offer better pricing than any other player in the segment,” says Dr. Sadhu.

Container handling equipment at the ICD include 24 road trailers, 17 forklifts, 13 dedicated rakes, 11 intercarting trailers, 8 cargo hand trolleys, 5 reach stackers of 40 tonne capacity each, 2 empty reach stackers, 3 electronic weighing scales (two with a capacity of 300 kg, and the other with a capacity of 1 metric tonne), 2 closed body trucks, 1 mobile sling crane of 20 tonnes, and 1 electronic weigh bridge of 60 tonne, among many others. CONCOR also provides office space to ICD users, space for palletisation, fumigation, and banking facilities.

Although both New Mangalore Port and ICD Whitefield are located in Karnataka, these two facilities haven’t been able to complement each other's business interests. “The sea port’s geographical location is a huge hindrance. Because of the Western Ghats, it’s not easy to reach the hinterland, either by road or by rail. For instance, ICD Whitefield has not been able to capitalise from regions such as Coorg, a region known for its major concentration of coffee planters, even though it is connected to the main port. Similarly, due to poor connectivity between the ICD and the port, it has not been able to extend container services to exporters and importers of other major commodities shipped through New Mangalore Port, such as raw cashew imports," Ameen Mohammed, Managing Partner, Hasan Hajee & Co., a clearing & forwarding agency based out of New Mangalore Port, tells The Dollar Business. However, still in FY2015, the ICD managed to register coffee exports and raw cashew imports of 8,557 TEUs and 7,149 TEUs respectively.

It's not that ICD Whitefield isn't aware of the logistics challenges, involving the movement of containers to New Mangalore Port. "Discussions are on with the authorities at New Mangalore Port to start an ICD," shares Dr. Sadhu. The ICD is also planning to develop a depot at Kadakola, near Mysore, to tap into cargo originating from the region, particularly from Nanjangud Industrial Area, Chikmagalur, Hassan and Coorg.

In FY2016, the Bengaluru Customs Zone earned a revenue of Rs.2,400 crore from Bangalore City Customs (it includes ICD Whitefield), making it the second highest revenue earner for the Customs Zone after air cargo. Although increasing investments in and around the city has opened new business avenues for ICD Whitefield, the rising number of business establishments has clogged the roads that connect the ICD with the rest of the world. It is time the local administration gives Bengaluru city’s lone ICD the attention it deserves. Even the state government should look beyond IT and ITES services, as the ICD imparts a much necessary equilibrium to the region’s economy.

Better late than never!

Dr. Anup Dayanand Sadhu Group GM, ICD Whitefield, Container corporation of india (Concor)

TDB: Please tell us in detail about ICD Whitefield and its cargo profile.

Anup Dayanand Sadhu (ADS): Inland Container Depot (ICD) at Whitefield started operations in 1989, and is today one of the biggest dry ports in the country. We handle both international and domestic cargoes; about 85-90% of our consignments is exim cargo and remaining 10-15% is domestic cargo. We have a 128-acre land bank, which the South-Western Railways has leased to us. We have 12 warehouses across 40,000 sq. mt. area, and currently, nearly 90% of the warehousing capacity is occupied. Recently, we have built another warehouse that spreads over 1,500 sq. mt. to meet the rising demand.

Granite is one of the major commodities we handle and it occupies about an eighth of our total warehousing capacity. We also have a cold storage to accommodate perishable goods. The other major export commodities we handle are gherkins, UPS, radiators, machinery, etc. The major import includes furniture, machinery, equipment, tiles, timber, among others. Speaking of domestic cargoes, most of them are old newspapers, polished granite slabs, rubber latex, plywood boards, etc.

The ICD has four-lane rail lines to move rail-bound containers. On an average, two to three trains run between the ICD and Chennai Port every day to transport exim containers. In addition, there are two trains per week that run between the ICD and Krishnapatnam Port. There is a train that runs with an interval of about 10 days between the ICD and Cochin Port, and another that runs between Whitefield and ICD Tughlakabad, once every 7 to 10 days depending on the demand to transport domestic cargo.

TDB: What are some of the major benefits for ICD Whitefield users?

ADS: One of the major advantages for the dry port users is the availability of in-house Customs clearance facility – neither importers nor exporters are required to visit the seaports for Customs related formalities. ICD has one Additional Commissioner, two Deputy Commissioners, and six Assistant Commissioners. It offers road and rail connectivity, as CONCOR is a multi-modal logistics company that can provide end-to-end logistics solution to clients.

We are also integrating coastal shipping into our logistics service, and since CONCOR has a pan-India presence, we offer better prices than other players in the segment. We offer regular services to major ports in the region, which means exporters can ship their cargoes without any delay. Another big advantage is the availability of rail wagons, adding to which the terminal provides eight dedicated rakes of 45 wagons for exim cargo, and five rakes for domestic cargo.

Container handling equipment at the terminal includes 7 reach stackers (with a cargo load capacity of 40 tonne each), one mobile sling crane (of 20 tonne capacity), and 11 inter-carting trailers to move containers inside the ICD. The ICD also has an electronic weigh bridge with a load capacity of 50 tonne to prevent overloading of cargo. We also lease out office space to terminal users. In short, we have the largest number of warehousing space in Bengaluru, which is one of the most well-connected cities in the country.

TDB: Why don’t you have any service to New Mangalore Port?

ADS: It is because the port doesn’t have good connectivity from the ICD. To transport goods to the port, they need to be first moved to Mysore, and from there they travel via Hassan. Moreover, a large part of the road includes ghat roads and their conditions are not suitable to transport goods. Also, at the moment, we don’t have a depot at the port, but we are planning to build one. As compared to New Mangalore Port, the connectivity is much better to Chennai Port – a new container handling port has also started operation near Chennai at Kattupalli.

TDB: What new services has ICD Whitefield initiated in recent years?

ADS: We have started reefer services to move outbound refrigerated containers from Whitefield to Chennai. Earlier, we used to receive import reefer containers, but now we have initiated export reefer containers to ship pharmaceutical items, mango, mango pulp and other agricultural products. Our IT infrastructure connects us with all ICDs in the country and it helps our customers track the location of containers. We also have a central monitoring system through CCTV cameras to ensure round-the-clock security inside the facility.

TDB: Which nearby regions does ICD Whitefield cater to?

ADS: Most of our cargo originates from in and around Bengaluru city, and nearby areas such as Bidadi, Nelamangala and Nanjangud. Some cargoes also come from places like Hosur in Tamil Nadu.

TDB: The road that connects the ICD to the national and state highways is very narrow and runs through a busy city. How do you ensure smooth movement of container trailers?

ADS: When the ICD was envisioned, Whitefield was away from the major commercial areas. But over the years, the city has expanded phenomenally, making Whitefield a major commercial area. The traffic has grown, creating heavy congestions on roads that connect ICD to the highways. And unfortunately, no additional infrastructure has been developed to cope with the growing traffic.

The local administration has restricted trailer movement through the city roads between 7 and 11 am, and between 3 and 9 pm, so we work at night

because of obvious reasons. The traffic is lesser and it helps us maximise our trailer movement during the window period that is permitted to us.

Exporters are discouraged because of the slow movement, but the local administration is planning six-lane roads from Hoodi to ICD, and from Indiranagar to ICD.

TDB: What challenges do you face?

ADS: We are facing stiff competition from road lines because rail bound cargo is shifting to road carriers. Rail freight has increased nearly 30-35% in recent years. Moreover, due to a drop in crude oil price in the international market, diesel prices have also come down. The national highways infrastructure has also improved a lot, which has increased the speed of cargo by road. For instance, it takes about 60 hours to transport cargo from Whitefield to ICD Tughlakabad by road, and road transport costs nearly 30-35% less as compared to rail transport.

Also, the current generation of multi-axle trailers is capable of carrying a much higher payload as compared to older trucks. Though road carriers are at an advantage for long-haul domestic cargo, we are in a better position when it comes to transporting export consignments to ports like Chennai and Krishnapatnam. Our export consignment is growing at an average 5-6% y-o-y, but we have registered a drop of about 30% in terms of domestic containers.

Rajiv Bhushan Tiwari Chief Commissioner of Customs, Bengaluru Zone

TDB: Please give a brief outline of the cargo and revenue profile of Bengaluru Customs Zone.

Rajiv Bhushan Tiwari (RBT): There are three Commissionerates in Bengaluru Customs Zone. The Bengaluru City Commissionerate is largely involved in Customs clearances related to ICD Whitefield; the Mangalore Commissionerate's activities include clearances at the New Mangalore Port; and we also have a Commissionerate that serves the airport and air cargo.

The zone earns maximum revenues from air cargo, which is about Rs.6,900 crore every year, followed by Bengaluru City Customs, which generates about Rs.2,400 crore (it includes ICD Whitefield). There is an acute shortage of staff, but we still manage to pull through as the Commissioner does not deal with day-to-day activities, as most of the Customs related formalities and inspection are done by field staff.

TDB: Customs Department has started implementing 'Integrated Declaration' under its Single Window Clearance project. Can you please elaborate on the new system and how it may help trade?

RBT: The Customs Department initiated the web-based assessment of exim cargo on April 1, 2016. Exim cargo also requires clearance from other statutory agencies like Animal Quarantine, Plant Quarantine, Drug Controller, FSSAI and Textile Committee, among others. However, the new initiative has brought all agencies under one web-based umbrella and it will help traders to get all statutory clearances through one platform.

TDB: Has the new mechanism been able to ease the work load on the Customs Department?

RBT: There will be no relaxation in terms of workload for the Customs Department. However, it will work in the favour of exporters and importers. They can also track the status of the documents on the web-based platform. It is too early to the evaluate the results as the new method was introduced only sometime back.

TDB: What are the major challenges that you encounter?

RBT: The biggest challenge is that all assesses want their cargo to get instant clearances, but the same promptness is not shown while filing required documents. Moreover, about 90% of the time, even if a consignment is caught with the courier, it’s very convenient for them to put the blame on Customs, whenever their clients complain about a delay in delivery.

We can start assessment only when the relevant documents are filed. However, the custodians of cargo – which could be the importer or the exporter or their CHA agents – generally delay the submission of documents with us. So, coordination between various agencies is also a big challenge.

The time between 3 and 6 pm means rush hour time for examination, hence we would like to give clearance to cargo in the morning hours. However, this isn’t possible because the state government has imposed a restriction on entry of trucks during day time.

But now the government has formed a customs clearance facilitation committee, headed by me. We convene meetings on a regular basis to address issues that the trade faces. We didn't have an FSSAI notified laboratory in Bangalore earlier, but now we have appointed private labs for quality check.

TDB: How was FY2016 for the Bengaluru Customs Zone in terms of financial performance?

RBT: There has been a tremendous decrease in earnings from gold as imports of the commodity in the zone has come down significantly. As compared to FY2015, we lost around Rs.1,000 crore in terms of revenue from gold, which is a drop of over 50%. Our revenue in FY2015 was Rs.1,804 crore from gold, whereas, in FY2016, it dropped to Rs.846 crore.

Earnings from other commodities (excluding gold) was Rs.10,100 crore in FY2016, as compared to Rs.7,510 crore in FY2015. So despite losing out on gold, we were able to meet the targeted revenue in FY2016. Also, we had not stopped any refund and drawback till the end of March 2015.

Among major exim products handled under the jurisdiction of Bengaluru Customs Zone, electrical machinery falling under Chapter 85 registered the highest growth in FY2016 – about 62% over FY2015.

In FY2016, major import commodities for the zone were medical and surgical equipment (17% growth), coal (17% growth), auto components (32% growth), machine and machinery tools (35% growth), and machine tools, parts and accessories (28% growth).

Revenue-wise, major importers in the zone for FY2016 were ABB, Apple, Volvo and Toyota Kirloskar. But, we have registered a negative growth in certain commodities in FY2016, which includes products like abrasive tapes (a fall of 19% in FY2016) and mobile phones (a fall of 36% in FY2016).

TDB: What are the major changes that you have noticed in the way the Department functions?

RBT: One of the positive changes is the attitude of Customs officials in recent years. India’s economy has been growing at a very good rate, so most of the products that were not available in the market earlier are now sold at competitive prices – say, unlike before, people don’t have to smuggle products like transistors into the country. And the Customs Department has adapted accordingly. The most visible change on the part of the Department is at airports. We have been able to extend about 99% passenger facilitations at the airport by disseminating knowledge through various social media platforms and mobile applications. Each year, about 16 lakh passengers travel via Mangalore airport, out of which 99% have availed the Green Channel facility. We have started public interactions on social media, where we try to address issues faced by passengers. We also have tied up with the State Bank of India to allow passengers at the Kempegowda International Airport to pay duty through debit and credit cards.

The All India Freight Forwarders Association has developed a software to keep track of the movements of containers, and we are now trying to implement the software at ICD Whitefield. We are looking forward to a mechanism wherein an India bound import cargo loaded on a ship will have an RFID sticker; or a mechanism to keep track of the consignments; or a process by which, once an export document is filed in a particular country, that document is made available to us instantaneously. This will help us reduce time required for cargo clearances. But, implementation will take some time, as all of the above require inter-governmental coordination.

Get the latest resources, news and more...

By clicking "sign up" you agree to receive emails from The Dollar Business and accept our web terms of use and privacy and cookie policy.

Copyright @2026 The Dollar Business. All rights reserved.

Your Cookie Controls: This site uses cookies to improve user experience, and may offer tailored advertising and enable social media sharing. Wherever needed by applicable law, we will obtain your consent before we place any cookies on your device that are not strictly necessary for the functioning of our website. By clicking "Accept All Cookies", you agree to our use of cookies and acknowledge that you have read this website's updated Terms & Conditions, Disclaimer, Privacy and other policies, and agree to all of them.