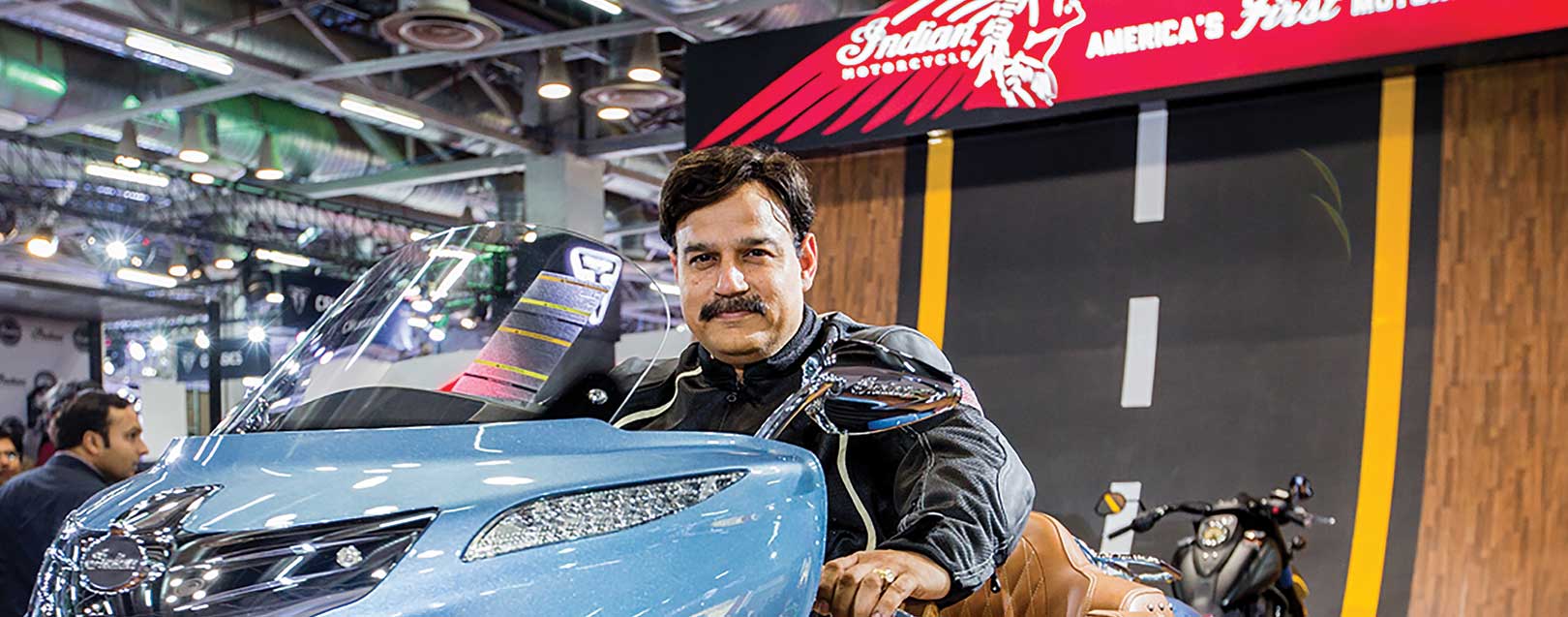

Pankaj Dubey, Country Head & MD, Polaris India Pvt Ltd

In 2011, when Polaris entered India, the market for all-terrain vehicles (ATVs) had zero competition. Pankaj Dubey, MD of Polaris India, and an auto industry veteran, saw this as a chance and a challenge. In an interaction with The Dollar Business, Dubey reasons why Polaris India is currently happy with importing completely built units (CBUs), and selling them at completely knocked down (CKD) prices.

Interview by Vanita Peter D’souza | May 2016 Issue | The Dollar Business

You have been associated with Polaris since it entered India in 2011. How has the journey been so far?

Pankaj Dubey (PD): Fantastic! When I joined the company, many people confused Polaris with our namesake software company, and there are still a few who do that. But the perception is fast changing, at least among the target audience, and the awareness has gone up. It gives me great satisfaction that in a span of about five years, we got to do so much in the country where the awareness level was negligible. Prior to our entry, the market for all-terrain vehicles (ATVs) in India as such was at a very nascent stage. In fact, till today, we are the only company in the off-road segment, apart from Suzuki which has launched its products in this segment recently.

TDB: In the current scheme of things, how important is India for Polaris?

PD: India is a huge strategic market for Polaris. We invested in the Indian market even before initiatives such as ‘Make in India’ were rolled out, purely because we foresaw India, Brazil, and China becoming the largest automobile markets in the near future. Strategically, we not only marketed our products in India, but we conducted India-centric market research and created products that are specific to the local requirements. These innovative products have been developed in collaboration with Eicher, which again, is a huge project.

TDB: Prior to Polaris, you were with a traditional auto company. What key differences have you noticed?

PD: Each market is different and comes with its own unique challenges and opportunities. In a traditional company, there is presence and competition. It’s an industry where you have to be innovative, launch products that are better than the competitors’, and market them differently to create an image in customers minds, so that they can lean towards your products. It’s more of a competitive analysis in a traditional auto company.

But when it comes to companies like Polaris, where there is neither an industry nor any competition, the strategy is totally different – we don’t even have a benchmark! A company that faces competition can strategise accordingly, but for an industry where there is no precedence, one has to think and act accordingly – it is risky, but that is where the challenge is. Also, in an established market, it is relatively easy to create and take away market share, whereas, non-traditional companies require hard work.

TDB: So, Polaris has no competitor?

PD: Yes, we have no competitors in India. Before Suzuki entered this segment in India, they spoke to me about the industry, and I gave them an honest feedback. I want competition so that the industry and the market can develop. We are confident about ourselves, as we are number one in the world in this segment. But with competition, it will be much better than fighting a lonely battle.

TDB: What about Indian motorcycle industry? You sell motorcycles as well!

PD: The Indian motorcycle industry is doing really well, especially at the top end. Alongside, the high-powered motorcycle markets are growing rapidly. We have the ‘Indian Motorcycle’ product line to tap this market and it’s another segment that we are excited about.

TDB: Can you tell us more about Polaris’ Indian Motorcycles? How is the business doing?

PD: In 2011, Polaris took over US-based Indian Motorcycle Manufacturing Company. After working really hard for two years, in 2013, we launched Indian Motorcycle’s products internationally. It took us about six months to introduce the entire range in India, and it was in May 2014 that our first dealership started. It has been almost 20 months since then and I am very satisfied with the performance. Our first showroom was inaugurated in 2014, after which five more were launched in 2015 – we plan to launch six more showrooms this year.

Most of our showrooms are located in tier I cities, mainly because our products are expensive. But keeping in mind that India is growing rapidly, we are looking forward to marking our presence in tier II cities this year, and within five years, we will be present in tier III cities as well.

TDB: Tell us more about Polaris’ joint venture with Eicher Motors.

PD: Eicher and Polaris have a 50-50 joint venture, and together we have created a product called Multix. Multix, as the name suggests, is a multi-utility vehicle and is targeted at independent business people who produce/buy products and sell it to another market. It is a pickup car with a power generator back-up. The product is manufactured in our unit, based near Jaipur. Eicher and Polaris have great synergies and our ideologies match. Eicher knows the Indian market and has a good supply base, and they are leveraging on their manufacturing. At the same time, Polaris is well-equipped with great technology.

TDB: The Indian auto industry has been burdened with heavy duties and taxes. What is your take on it?

PD: As far as Indian Motorcycle and Polaris are concerned, I think the government policies require a lot of changes. To manufacture a high-quality bike or car, one needs a capable and willing vendor. To sell abroad, one has to improve the component quality. Given that we do not manufacture high-quality components, we have to import them, because of which we have to pay high duties, and thus, exporting is not an option for us.

TDB: The entire product range of Polaris India is imported through CBU route from US. Is this the reason that Polaris products are expensive?

PD: Component manufacturers in India are not really interested in producing high-quality products because the off-road vehicles in the country are almost invisible. But there are a few smart manufacturers who have seized the opportunity and are producing globally in large volumes – they are in talks with us. Also, we have a team in India trying to locally develop components, but the entire process is a bit slow. At the moment, our strategy is to develop our market, let the buyer enjoy our products and spread the word. Until then, we will keep a very thin margin in India – import completely built units (CBU), but operate at completely knocked down (CKD) prices.

TDB: What has been your experience dealing with the defence sector and state governments?

PD: One of the first such meetings I attended was in 2011 with the Indian Army, and it wasn’t a happy experience. We were told that the whole process will take time, but they wanted us to make a product for them and give a year or two as a trial period. We were also told not to expect any order before five years. And in case they want to proceed with the order, they would want the same product which was manufactured as a trial bike five years ago. If you ask me to make the same product that was manufactured five years ago, I don’t think any vendor will meet the expectation. It was a very frustrating experience, but fortunately, we were the only company that produces superbikes in the country, and so, there was no competition.

Gujarat Police were the first to order bikes from us and the deal happened very quickly – we cleared the test in two attempts and got the order. So the experience varies from customer to customer. After our success in Gujarat, we got orders from Tamil Nadu, Kerala, Nagaland, Jammu & Kashmir, among others. Indian Army also bought some products. I would say our government is progressing in the right direction. They no longer just do the talking, but their working system has also become more efficient.

Get the latest resources, news and more...

By clicking "sign up" you agree to receive emails from The Dollar Business and accept our web terms of use and privacy and cookie policy.

Copyright @2026 The Dollar Business. All rights reserved.

Your Cookie Controls: This site uses cookies to improve user experience, and may offer tailored advertising and enable social media sharing. Wherever needed by applicable law, we will obtain your consent before we place any cookies on your device that are not strictly necessary for the functioning of our website. By clicking "Accept All Cookies", you agree to our use of cookies and acknowledge that you have read this website's updated Terms & Conditions, Disclaimer, Privacy and other policies, and agree to all of them.