UNION BUDGET 2016: THORNS AND ROSES

But will these new structures really give manufacturing a boost?

Indranil Das | The Dollar Business

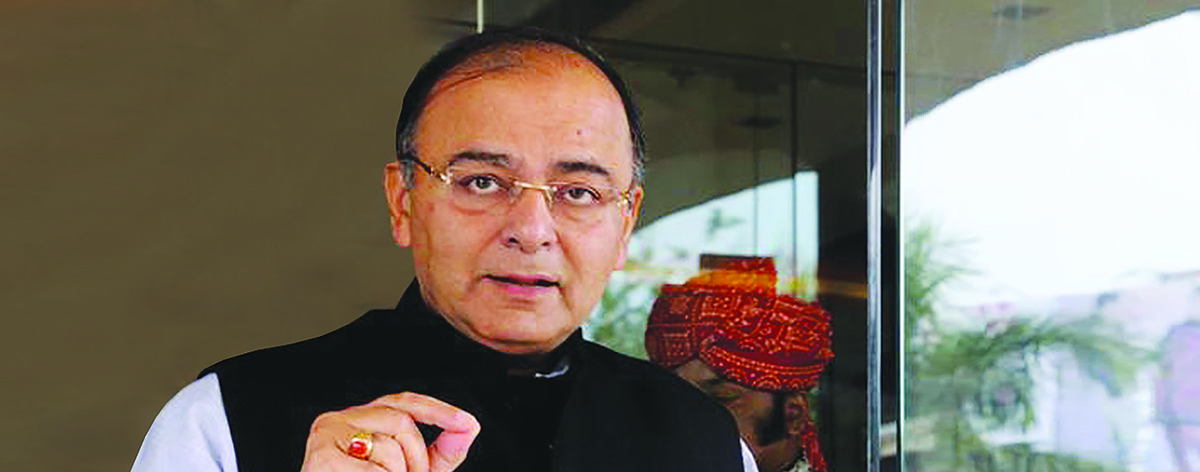

The Union Budget, as is always the case, this year too was applauded by some (for maintaining a focus on infrastructure, rural development, and being within the fiscal target) and criticised by many (including the opposition, for being a budget with an eye on elections in key states). Nevertheless, the Union Budget 2016 was a budget where Finance Minister did give everyone something, via his ‘nine pillars of focus’. While he made a total outlay of Rs.2,21,246 crore for infrastructure and an allocation of Rs.87,765 crore to rural sector, he kept aside Rs.1,700 crore for setting up 1,500 Multi Skill Training Institutes under ‘Skill India’ programme apart from allocating Rs.25,000 crore towards recapitalisation of public sector banks. He also reduced the customs duty and/or special additional duty (SAD) on several key raw materials/components, either to make them available cheaper to Indian manufacturers, address duty inversion, or address CENVAT credit accumulation, along with increasing the customs duty on a few items to make domestic manufacturing more competitive. With India being described as a ‘shining star’ in a gloomy global economic climate, Jaitley could proudly spout an impressive GDP growth rate of 7.6%. But at the same time, with elections round the corner in key states, the government had to be sensitive to political realities and yet the development agenda, being the plank on which the BJP came to power, could not be left behind. True to form though the Union Finance Minister consistently pushed Make in India, Prime Minister Modi’s key initiative to make India a global manufacturing hub. So, while Jaitley has put emphasis on road and rail infrastructure, ease of doing business, he has tried to rationalise corporate taxes and safeguard the domestic manufacturing sector through changes in customs duty and excise duty. But has he, really? And more importantly, how?

Amendments made to the cenvat credit rules 2004 have received wide acclaim

Infra Push

A key pain point that has been brought up, time and again, by manufacturers and exporters is the lack of proper infrastructure and, hence, the high cost of logistics in India as compared to its peers globally. In fact, a report by the Indian Foundation of Transport Research and Training (IFTRT) states that developed countries spend about 9-10% of their GDP on logistics and transportation while India spends about 13-14%. This is largely a result of diverse geographic conditions and poor core infrastructure. And, not to say, has only put Indian products on the back foot in international markets. Finance Minister has tried to address this issue by allocating Rs.55,000 crore in the Budget for roads with additional Rs.15,000 crore to be raised by NHAI through bonds. Together with the capital expenditure of the Railways, the total outlay on roads and railways will be Rs.2,18,000 crore in FY2016-17. He has also allocated Rs.800 crore to the National Waterways project which will go towards development of new ports and improving existing port infrastructure.According to Siddharth Jairaj, Director, TVS Dynamic Global Freight Services Ltd., the budget has struck the right note with respect to infrastructure development. “Improvement of infrastructure is one of the main requirements for growth and this has been highlighted time and time again. It’s a welcome move by the government. It will not only give a boost to infrastructure development, but will also create employment,” Jairaj tells The Dollar Business. Although the government has initiated the process of reorienting strategies and infusing funds to transform India’s major ports into viable and productive assets, the real change could still be hundreds of miles away.

Easing Credit Flow

The Finance Minister has also proposed to amend the Cenvat Credit Rules 2004 with the purpose of improving credit flow and reducing the compliance burden and associated litigations, particularly those relating to apportionment of credit between exempted and non-exempted final products or services. Changes are also being made in the provisions relating to input service distributor, including extension of this facility to transfer input services credit to outsourced manufacturers, under certain circumstances. This seems to be a good move from Finance Minister as the amendments in these rules will not only improve the flow of credit, but will also minimise the cascading effect of tax on tax paid by manufacturers, thus providing a boost to Make in India campaign. In fact, one of the biggest benefits to manufacturers is that the definition of ‘capital goods’ has been expanded to include more products. For instance, the exclusion of ‘equipment or appliance used in an office’ has been deleted from Rule2(a)(A)(1). The effect is that such office equipment or appliance, if falling under chapters 82, 84, 85 and 90, or being components, spares or accessories of these though falling under other chapters, would now become eligible for taking Cenvat credit of the duties paid on them. Further, low-value capital goods, the value of which is up to Rs.10,000 per unit, have been included in the definition of ‘input’ with the effect that items that otherwise fall into the definition of ‘capital goods’ will now be treated as inputs for the purposes of Cenvat credit. This will enable full credit to be taken upon receipt of the goods, without the restriction of 50% in the year of receipt as applicable to capital goods. Also, the FIFO mechanism for utilisation of Cenvat, which was introduced in the Union Budget 2015, has been done away with. The FIFO rule had attracted negative reactions from the industry last year. With an eye to the realities of the time, and the present manufacturing landscape, the amendment to the Cenvat Credit Rules will enable manufacturers with multiple manufacturing units to maintain a common warehouse for inputs and distribute these inputs with credits to the individual manufacturing units. Industry bodies across sectors have welcomed these changes and believe that the new rules will lead to easier flow of credit and less confusion and hence less litigations.

A Farmer’s Market?

The Union Budget 2016 seeks to double the income of farmers in a five-year time frame. FM, in his speech, said that this is a move towards “giving farmers income security for the food security that they give the country.” With only around 46% land under irrigation and the rest dependent on the vagaries of monsoon the agri-commodities sector has seen tough times over the last couple of years, with prices of pulses and onions shooting up due to shortage in domestic production and becoming political flashpoints. India had to resort to imports of pulses and onions, causing a drain on the exchequer. In fact, agri-commodities exports have been on a continuous decline for the last 15 months, further hurting prospects for India’s exports growth. Now with FM announcing a term irrigation fund to be created in NABARD with a corpus of Rs.20,000 crore and bringing 2.85 lakh hectares under irrigation, agriculture may hope to no longer be dependent on monsoon. Also the target for agricultural credit has been raised upwards to Rs.9 lakh crore in FY2016-17 from the Rs.8.5 lakh crore in FY2015-16, and a provision of Rs.15,000 crore has been made for interest subvention to reduce the burden of loan repayments on farmers. A word of caution here, successive governments have announced measures to bring more land under irrigation, the implementation on the ground though is yet to be seen. But with the government trying to remove the tag of ‘suit boot ki sarkar’ and giving priority to the agricultural sector, we may see exports of agri-commodities rising. Meanwhile the cashew industry received a jolt in the form of a 5% Basic Customs Duty (BCD) on cashew nuts in shells (HS Code: 08013100). Earlier, the BCD on imports of cashew nuts in shells was ‘zero’. This has created a furore amongst cashew processing units across the country. “The duty would sound the death-knell for the cashew processing industry in the country,” says Karnataka Cashew Manufacturers Association President Bola Rahul Kamath. And why not? With 5% BCD, 4% special additional duty (SAD) and a 3% education cess, the total duty on imports of cashew now comes to 9.27%, turning the books of several small cashew processing units into red. Interestingly, India does not produce enough cashews to meet its domestic demand and as such relies on its imports – India imported a total of 9.75 lakh tonnes of cashews in FY2015, up from 9.07 lakh tonnes in FY2014. Chairman of Cashew Export Promotion Council of India (CEPCI), P. Sundaran, reacting to the Budget announcement says that the import duty would adversely affect the cashew processing industry in India. “We have lost the competitive advantage. The government should introduce enough incentives for exports to mitigate the impact,” he tells The Dollar Business. The cashew processors and exporters in the country have been passing through tough times owing to an increase in prices of raw cashew nuts against declining prices of finished product in international markets. As per CEPCI, at inflated prices of raw nuts, processing and exports will become unviable and might lead to closure of many factories. Interestingly, exports of cashew nuts (shelled) from India (HS Code: 080132) have fallen from $913.86 million in FY2012 to $887.46 million in FY2015. With input costs rising, it is likely that exports of cashew nuts will suffer more in days to come.

Exports of processed cashew could suffer due the levy of a 5% BCD on cashew nuts

Make In India

As in last year’s Budget, ‘Make In India’ found several mentions in this year’s Budget speech too. In fact, this year’s Budget makes in pretty clear that the Narendra Modi government has made up its mind about a larger share of manufacturing in GDP, with the programme being its primary tool to take the country on a high growth trajectory. “Incentivising domestic value addition to help ‘Make In India’ was one of nine pillars on which the Budget 2016 was based.” So, making an attempt to correct the prevalent inverted duty structure, which has been hurting the domestic manufacturing since long, FM reduced customs duty and/or special additional duty (SAD) on several key raw materials/components across sectors, while increasing it in the range of 2.5% to 10% on many finished products.

For instance, in textiles (Chapter 54 and 55), BCD on specified fibres and yarns have been reduced from 5% to 2.5%. The products included under this facility are nylon 66 filament yarn, Polyester anti-static filament yarn, aramid flame retardant fibre, para-aramid fibre, nylon staple fibre, nylon anti-static staple fibre, modacrylic fibre and flame retardant viscose rayon yarn. This measure will not only help in bringing down the input cost for several technical textiles manufacturers in the country, but will also make its exports from India more competitive globally. Technical textile holds enormous export potential with demand for it being high from the developed countries. India, however, has been lagging behind its peers – Vietnam and Sri Lanka – in this product category. R. K. Dalmia, Chairman, Texprocil, too welcomes the move and says, “this should make exports from India more competitive.”However, the textile industry is unhappy about the 2% excise duty that has been levied on branded readymade garments [falling under Chapters 61, 62 and 63 (heading Nos. 6301 to 6308), except those falling under 6309 00 00 and 6310] above a value of Rs.1,000. Animesh Saxena, Managing Director of Neetee Clothing, talking to The Dollar Business says, “The excise duty on readymade garments has increased, the tariff value enhanced and even the basic fibre used (PSF / PFY) is proposed to be taxed at a higher rate. This is definitely going to impact the textile industry in the country and will affect the cost structure of the entire value chain of the readymade garments industry.”

The electronics and technology hardware industry has also received a significant ‘Make In India’ push. The duty structure for the mobile phone industry has been modified to dis-incentivise semi knocked down (SKD) manufacturing of mobile phones. SAD exemption on charger, adapter, battery and wired headsets, speakers for use in manufacture of mobile handsets including cellular phone has been withdrawn. Also, import of populated printed circuit boards (PCBs) by manufacturers would now attract a 2% duty. The same is the case with E-Readers. However, interestingly, BDC and CVD has been exempted on inputs and parts for manufacture of charger, adapter, battery and wired headsets, speakers of mobile handsets including cellular phone and inputs and sub-parts for use in manufacture of parts of charger, adapter, battery and wired headsets, speaker. BCD on parts and raw material for manufacture of E-readers is being reduced to 5% subject to actual user condition. The intention appears to be to create a manufacturing ecosystem through a process of backward integration. While this may be a step in the right direction what also needs to be seen is whether the indigenous mobile phone manufacturing industry is capable of ‘Making in India’. Pardeep Jain, Managing Director, Karbonn Mobiles in a statement said, “This is disheartening and is likely to stifle the growth of Indian smartphone players and impact their price competitiveness. The parts and components ecosystem in the country is still in its nascent stage. Government should have allowed for a gestation period for local handset players to strengthen their manufacturing capabilitiesbefore withdrawing tax exemptions on completely built units.’’ As exemplified by Jain, this brings into question how the new mobile phone manufacturers in the domestic market, who do not have requisite technology and manufacturing wherewithal cope in a competitive market. It seems the much in the news ‘Freedom 251’ phone, whose cost structure had raised questions of feasibilty, will remain a pipe dream. Chinese mobile phone manufacturers, with their low cost structures, will keep giving indigenous manufacturers a hard time. Coming to the engineering sector, customs duty has been raised from 5% to 7.5% on primary aluminium products falling under HS Codes: 7601, 7603, 7604, 7605, 7606 and 7607, and from 7.5% to 10% for other aluminium products [HS Codes: 7608 and 7609]; and for zinc alloys [HS Code: 790120] from 5% to 7.5%. While this will help protect large domestic manufacturers, the MSME sector will suffer. Naveen Jain, Managing Director, Dayachand Engineering, a Muzaffarnagar-based manufacturer says, “For aluminium alloys and zinc alloys the enhancement in BCD is a negative with respect to smaller players. How will this encourage ‘Make in India’ for MSMEs in electrical and other aluminium based sectors is anybody’s guess?” With respect to increase in BCD on primary aluminium from 5% to 7.5% it is interesting to note that India’s trade surplus in this item has risen significantly from $14 million in CY2011 to $744 million in CY2015. This increase also comes at a time when hit by the slowdown in China, the largest consumer of aluminium, smelter capacity use worldwide is down by a third. Hindalco, the country’s largest aluminium maker, had also announced the closure of their smelter in Hirakud, while Balco, part of the Vedanta Group, the other large player in the industry had also started shutting its rolling mill in Korba, Chattisgarh. In this state of affairs, it is but obvious that major aluminium makers are happy with this hike in duty with T. K. Chand, Managing Director, Nalco hailing the move as a positive step towards protecting the domestic industry from cheap imports. It seems the government has sought to give ‘Make in India’ a boost through rate changes in customs duty, however across sectors there is a feeling that only large manufacturers will benefit from the changes in duty structure and MSMEs feel betrayed by the budget. With MSMEs accounting for 40% of total exports it is difficult to see how the decline in exports over the last 15 months can be arrested by this Union Budget.

Boost To Mro

To stem the outflow of foreign exchange and give a boost to the Maintenance, Repair and Overhaul (MRO) industry, the Budget has exempted tool kits used for maintenance, repair, and overhauling of aircraft from both customs and excise duties. And it was the need of the hour given that a $600-700 million MRO business is going out of the country. In fact, in an exlusive interaction with The Dollar Business, Ashok Gajapathi Raju, Union Minister for Civil Aviation, GoI, too raises this issue. “MRO issues need to be addressed because that will generate a lot of jobs. As of now, barring the public sector airlines, private airlines are going abroad for their routine maintenance. They are going to places like Singapore, Dubai and Sri Lanka. From Indian players point of view, it’s a $600-700 million business going out of the country. The impediments seem to be from two sides, as far as GoI is concerned – one is the service taxes and the other is Customs duties.” The finance bill also allows foreign aircraft brought to India for MRO work to stay up to 6 months or as extended by the DGCA. The aircraft can carry passengers in the flights at the beginning and end of the stay period in India. This is expected to bring in foreign carriers to the Indian MRO market, providing a boost to the Indian civil aviation industry by creating an alternative revenue streams.

A Fine Balance

Arun Jaitley had mentioned in his Budget speech that the theme of the Budget was to “Transform India”. It does seem that the government has the right intentions, from the many changes introduced in both direct and indirect taxes as well as allocations towards the rural and infrastructure sector. While in a democracy there will always be political compunctions (and with elections in key states coming up soon it was necessary to play to the vote bank), the government has also remained focussed on its development agenda. But when it comes to transforming India, only time will tell if the Budget 2016 will be able to do that by making India a global manufacturing hub and stem the tide of declining exports from the country.

to success.

to success.